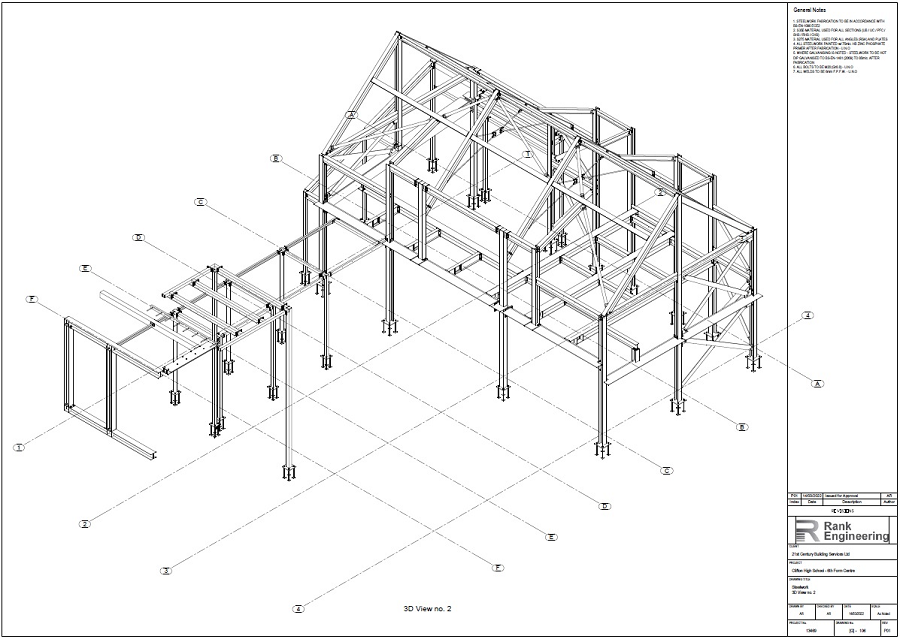

Structural Steelwork Bristol Oxford UK

Showcasing some of Rank Engineering’s favourite UKCA structural steelwork projects over the last couple of years. Obviously, we don’t take pictures of all of them, but we are always busy with BS EN 1090-2: 2018 steel fabrications in Bristol, Oxford and all over the UK in fact. From roof steelwork in Bristol’s City Centre to steel frame buildings in the countryside, if it’s structural steel you require supplied, manufactured and installed, then please do not hesitate to call us on 0117 955 1298 or email me; the Welding Coordinator here at Rank Engineering- Stephanie@RankEngineering.co.uk. Alternatively, you can submit your quotation enquiry using the following link:

Contact us – Rank Engineering Structural Steelwork Bristol

Project Management Supply Manufacture Installation

Rank Engineering will engineer design solutions for you, with end to end project management, from full construction site surveys, through steelwork fabrication drawings; design and development, to complex, mathematical, crane lift steel erection.

Quick Lead Time Metal Fabrications

With our on-site brake press, guillotine and plasma cutter, our quick lead time is second to none- as we can manufacture all the steelwork, under one roof, on the Barton Hill Trading Estate (including the steel profiles always required in structural steelwork, with our new Esprit Lightening S CNC Plasma Table). I must admit, it is extremely convenient having a state-of-the-art metalwork factory at your fingertips, when it comes to a quick turnaround on metal fabrications.

Architectural Fit-Outs All Metals

Rank Engineering have worked with some of the biggest construction companies in the UK. With our continued UKCA certification of MAG, FCAW and TIG welding and ongoing Factory Production Control, we are proud to be Approved Suppliers and Bristol’s ‘Go-To,’ structural steelwork fabrication company. What really sets us aside from our competitors though, is the diversity of projects we undertake. Since we can fabricate any metal, such as steel, aluminium, stainless steel, copper and brass, we are often employed by the same contractor on huge projects, containing structural steelwork, architectural metalwork and custom metal fabrications. Whole building renovations and fit-outs for example. With multi-faceted projects like this, it is often beneficial to use the same manufacturer, as it takes a ‘knot out of the rope.’ With fabrications manufactured ‘all under one roof’ this reduces the overall cost and time.